The transforming business world in the contemporary global market signifies a varied range of rapid changes in overall business operations. Supply chain management shows enormous changes and reformations through technological implementations and extensive globalization. According to Bai et al. (2021), the emergence of the COVID-19 pandemic has created significant disruptions in the supply chain process of one of the leading technology companies Samsung. Affecting the value chain approaches by creating an enormous impact on the global supply chain of the business, the pandemic has created challenges in creating the integrity of the company in the global market.

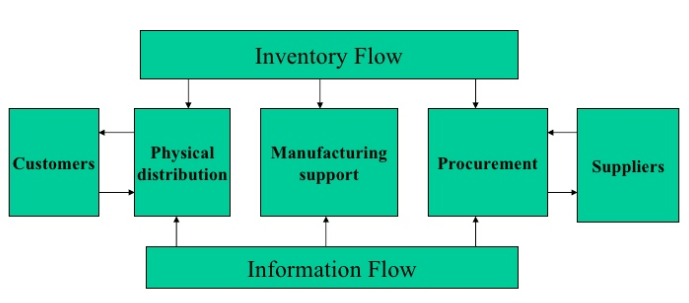

Logistics and physical distribution were frequently used interchangeably. The functioning of the global transportation system of the company focuses on the inbound and outbound logistics for different manufacturing plants in countries like Korea, China, Taiwan, and Brazil which signifies a large-scale logistics system incorporating the different Stock Keeping Units (SKUs) across the world (Samsung-About Us, 2022). Samsung focuses on inventory management as a component of the supply chain that covers a range of responsibilities, including order fulfillment, maintaining stock storage, controlling product sales, and controlling and supervising client purchases. However, this study focuses on critically analyzing the diverse range of aspects of the supply chain by investigating the short-term and long-term impacts of the pandemic.

Note: Do you need any Assignment Help at affordable prices? Contact us!

Logistical movement in Samsung and the impact of the COVID-19 pandemic on the logistical approach of the company

Physical distribution is the branch of business management in the case of the transportation of unfinished goods and finished goods as well as the creation of transportation systems. Samsung has significant developments in customer support, order processing, inventory control, transportation, logistics, and packaging are some of the key responsibilities for the physical movement of the materials (Staub, 2022). However, an integrated logistics system of the business organization has the power to give businesses a competitive edge.

The impacts of the COVID-19 pandemic on the three major aspects of the logistics of Samsung

Impacts on Inventory

Before production, transporting, or selling, goods are stored in a warehouse and are referred to as inventory. In the post-pandemic market, the global leadership of Samsung emphasizes the business network of the technology business for the recovery of the supply chain operations. After the pandemic, the company was forced to localize the resources and processes to create e higher degree of convenience for the business operation which created enormous pressure on the inventory management system. Finished items, Work in Progress (WIP), raw materials and components, and maintenance, repair, and operation (MRO) activities are the four basic categories of inventory management of the company (Abdelshafie, Fatouh, & Rashid, 2021). The theoretical framework of MRO signifies effective integration of the inventory functioning according to the market demand for the products. Thus, for a supply chain to function at its best, inventory management is crucial since it plays a significant role in creating sales and profits.

Impacts on Global Distribution System

The global distribution system of Samsung covers a wide range of operations and procedures, including supply chain management, inventory management, warehousing, and packaging. The impact of the pandemic on the global logistics system of the company signifies the reassessment of the global distribution network due to supply and demand shocks in the large market. Focusing on the bottlenecks in the supply chain and access to a large number of potential customers, Samsung significantly struggled to develop trust and customer convenience on a large scale during the crisis period of the COVID-19 pandemic. Distribution functions of the company refer to the outbound organizational logistics system to improve the effectiveness of the logistics channels from the supplier to the customer, signifying the influence on costs and performance.

Influence on the E-supply chain

In this digital era of supply chain management, business operations that integrate e-business strategies with supply chain processes are referred to as e-Supply Chains. Applying a wide range of online business technologies to support and optimize value-adding activities in supply networks is what e-supply chain management entails at Samsung. The Diffusion Theory of Innovation shows the company is adopting advanced digital technologies as the fundamental structural block of the r-supply chain on a global scale. However, the fundamental distinction between logistics and supply chain management is that the former involves the integration and maintenance of the flow and storage of items within an organization, whilst the latter involves the coordination and management of the movement of a company’s supply chains (Tian et al. 2019).

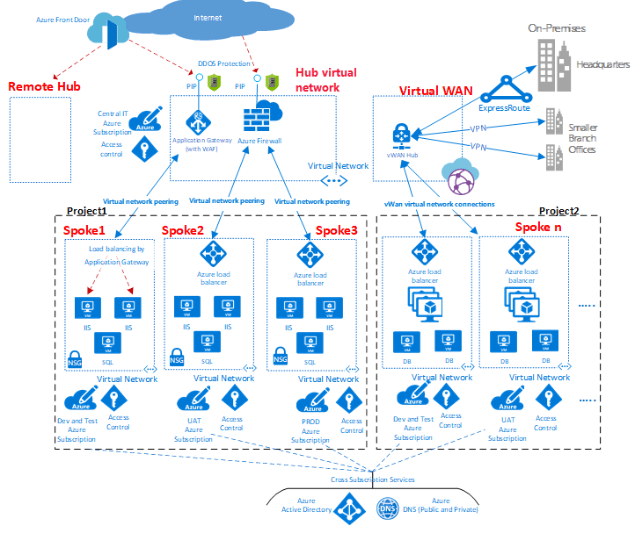

Hub-and-Spoke Logistics Network Model

As the global business environment is shifting towards digitalization, Samsung is adopting cloud computing in the Hub-and-Spoke logistics network to enhance the overall capacity of supply chain management. The theoretical framework of the model shows that the centralized and integrated model of the Hub-and-Spoke logistics network allows the company to derive better control and tracking of the movements from distribution centers to resourcing of the raw materials. As the COVID-19 pandemic disrupted the material mobility in the global supply chain system, Samsung is now forced to emphasize creating a centralized framework to enhance risk management in the logistics network. Incorporation of Server Active Directory and DNS services through creating integration among the different units of the global business, Samsung has created an effective IT infrastructure to operate the movements of the materials and commodities more systematically. This centralized approach allowed Samsung to restart the logistics system with significant potential for a fast recovery after the break out of the COVID-19 pandemic.

Supply Network Design of Samsung and the impact of the pandemic on inventory and control

The rising trends of data-driven supply chain operations and the incorporation of technologies like cloud computing and blockchain technologies are reshaping supply network design significantly. For instance, location intelligence is playing a crucial role for Samsung in creating a cost-effective approach to supply chain management (Gultom & Wibisono, 2019). On the other hand, technologies like IoT and Big Data analysis are being adopted for aligning supply chain management with the overall global business intelligence based on supply and demand in the global market. However, the supply network design of Samsung signifies three fundamental components that conceptualize the overall global system to create a competitive edge by enhancing service efficiency in the market.

Purchasing or sourcing and its impacts on inventory management

Incorporation of advanced technologies in sourcing the raw materials, the supply network design ensures a higher degree of environmental sustainability and service efficiency through the inventory management framework of the supply network. Samsung helps its suppliers uphold international laws and standards to fulfill its social and environmental obligations (Smith-Ditizio & Smith, 2019). However, the COVID-19 pandemic enormously impacted the procurement of materials due to the global insurgency during the crisis period. Additionally, the company’s sourcing strategy is now forced to focus on risk management to reduce violations inventory disruptions, and environmental repercussions during logistics operations in different parts of the globe.

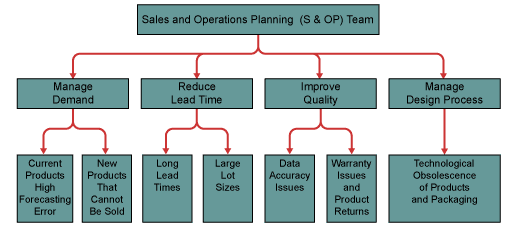

Planning or scheduling and its impacts on inventory management

Planning in supply network design signifies an adverse range of focuses on production, logistics, distribution, and resources efficiently. Samsung ensures the planning in these segments by creating an integrated system of procurement and operational strategy implementation. Apart from that, the company deals with a wide range of suppliers and distributors, and the supply network was heavily affected by the shutdown of the suppliers and the lockdowns in the commercial markets during the pandemic. Samsung faced a significant shortfall in the skilled workforce in the manufacturing plants after the emergence of the Covid-19 pandemic which refers to an 11% decrease in sales in the fourth quarter of 2020. On the other hand, the planning of physical distribution was largely impacted by the pandemic as the stagnation in functioning on the suppliers’ side and the transportation system stalled after the emergence of the pandemic.

Logistics and impacts on inventory management

Logistics refers to the integrated approach to transportation, storage, handling, cataloging, and packaging in the manufacturing and distribution process. According to Treiblmaier et al. (2020), the current trends of digitalization and technological adoptions signify the integrated network of Samsung that efficiently emphasizes inventory chain management through movement and storage capacity enhancement. The process starts with raw materials, goes through manufacture and distribution, and ends when finished goods are delivered to the consumer or when things are returned to their original location. The disruptions in moving the ments of raw materials and products during the pandemic in 2020 influenced the inventory to withhold the response to the market demand signifying creating a bottleneck situation in the supply chain.

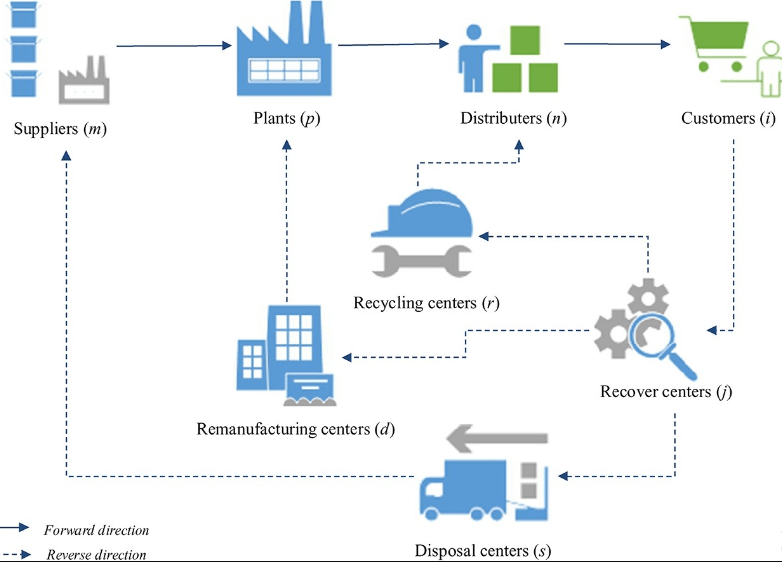

The Closed Loop Supply Chain Management (CLSCM) signifies that Samsung is adopting effective technological innovations to create integrity and a higher degree of efficiency to develop flexible interactions among different SKUs. Apart from that, the forward and reverse direction of the supply network design refers to the outbound and inbound logistics through effective global collaborations with the logistics businesses (Seyedan, & Mafakheri, 2020). Reverse Logistics ensures to collection and process of returned a wide range of electronic products or parts of products to ensure the sustainability of the operations. The collaborations in the global market refer to the Forward Logistics in the chain through procurement of materials, production, and distribution. However, reverse logistics experienced significant pressure in the recovery period of the COVID-19 pandemic due to a decrease in market demand after the break out of the pandemic.

Technologies for Logistical and Operational Flow in the Distribution or Fulfillment Centre

The logistics network of Samsung signifies the incorporation of a global network system for movement of the materials and products with a higher degree of service efficiency. The technology conglomerate company has created an integrated logistics approach for the movement of the high-scale manufacturing and distribution of a wide range of electronic products in the global market. The innovations and advanced technologies are effectively creating better control of the logistics network and contributing to service efficiency (Tay & Loh, 2021). For instance, the adoption of cloud computing in the company signifies the robust logistics network model by developing an effective IT infrastructure. However, the logistics system was disrupted by the impact of the pandemic directly and indirectly due to health measures like social distancing and serial lockdowns in most countries in March 2020. According to Lysons & Farrington, (2020), this factor created a challenging situation for the global logistics network as the company relies on efficient logistics services for the production and distribution of the products. The only way to make it work is to establish certain operational efficiency-focused rules and a production planning methodology. However, the technological incorporation ensures the development of a highly efficient global network influencing the value chain of Samsung positively (Sundarakani et al. 2019). The theoretical approach of technological implementation in supply chain management ensures a diverse range of service upgrades as well as the sustainability of the overall business process.

The resource-based approach in the technological implementation of IT infrastructure signifies the enhancement of supply chain capability in a multidimensional manner. However, using the value of information to distinguish the firm’s competitive advantages and distinctiveness, organizational IT adoption is considered in this paradigm as a strategic investment in the organizational capability of exploiting information resources. The fundamental idea is that a company will maximize its supply of resources or goods from specialized providers rather than producing them in its capacity in a perfect market (Seyedan, & Mafakheri, 2020). Companies have hierarchical connections with their suppliers through repeat, contract-based transactions. Samsung is focusing on creating a higher degree of implementation of digital technologies in the post-pandemic global marketplace to ensure capability enhancement in the supply chain functioning.

Data Analytics

Data intelligence is one of the most crucial technological implementations of Samsung which ensures a significant amount of quality enhancement in procuring business and market data. The company is now focusing on effective risk assessment by collecting and analyzing a vast range of data in different layers of the supply chain to create sustainability and growth in the post-pandemic world. As the pandemic created a significant disruption in logistics and inventory management, technologies like Big Data analysis and Natural Language Processing (NLP) are playing a vital role in enhancing the efficiency of warehousing and inventory management (Ivanov, 2021).

Cloud computing infrastructure

As the company operates through the Hub-and-Spoke Logistics Network Model, adopting cloud computing services is reshaping the global logistics activities of the company. On the other hand, significant innovations in Software-as-a-Service (SaaS) and Platform-as-a-Service (Paas) are playing a vital role in managing the e-logistics of the company (Ivanov, Tsipoulanidis, & Schönberger, 2019). These systems effectively control and track the material flow in fulfillment centers as well as in distribution centers.

Automation and robotics

The leading company working in semiconductor technology, Samsung significantly focuses on automation and robotics to create a higher degree of integration in the global supply chain. The company focuses on implementing automation in different layers like inventory management and warehousing to ensure customer-centric services by minimizing the time of procurement of the products as well as the raw materials.

You may also like reading AI In Supply Chain Management

Blockchain technology

Samsung is playing a leading role in incorporating blockchain technology in supply chain management to create highly integrated and trusted services that can enhance customer satisfaction and experience. Developing a Trusted Executive Environment (TEE) is one of the primary focuses of blockchain technology which will create an integrated platform of global payment in the supply chain (Tan et al. 2020). The company is ensuring effective payment approaches on the suppliers’ end as well as on the fulfillment centers or e-commerce through technological development in this domain.

Modern methods of inventory management of Samsung supported by the Re-order model and EOQ

Inventory management is one of the crucial elements of supply chain management in the contemporary world. Samsung experienced a disruption through the lower degree of functioning in inventory management due to the change in demand in the market and operational barriers in the larger network. However, the implementation of the Lean Six Sigma tool in Samsung ensures decreasing the wastage of raw materials through strategic approaches to system development. However, the company is significantly implementing advanced technological developments like AI and automation in defining the DMAIC model of Six Sigma in inventory management. The model signifies defining, measuring, analyzing, improving, and controlling the process in inventory to enhance the effectiveness and efficacy of the overall global supply chain. On the other hand, building and simulating a supply chain is the process of supply chain network design, which aims to better understand the costs and times involved in delivering items to the market based on the resources and locations.

Samsung has the potential to implement the Economic Order Quantity (EOQ) model and Reorder model integrated with the Six Sigma Approach. Economic order quantity (EOQ) enables the business to estimate costs and determine the appropriate order size, enabling them to meet demand without going overboard (Efrilianda & Isnanto, 2018). Samsung’s inventory strategy signifies computing EOQ to reduce holding expenses and surplus inventory. On the other hand, the minimal amount of stock required for a certain product is known as the inventory reorder point in inventory management (Park et al. 2021). Reordering of that specific product begins when the company achieves that stock level. The strategic implementations of the model signify the incorporation of a wide range of components like cost assessment and wastage analysis as the company is required to focus on extensive manufacturing scale and global scale logistics. The effective strategic framework of Lean Six Sigma allows the company to evaluate the nominal costs for resourcing and material procuring throughout the supply chain. Apart from that, the case study of the company shows that the information system of the company supports the strategic implementation through the IT infrastructure by defining the organizational objectives and influence in the global market through delivering the products for a higher degree of customer convenience.

Samsung continuously strives to create a sustainable business ecosystem based on the principles of justice, openness, and co-prosperity in conjunction with its international suppliers. However, the incorporation of these models along with Lean Six Sigma allows the company to create better control of inventory. Inventory control of Samsung is now highly integrated with these models through implementing advanced technologies like automation and cloud computing. Apart from that, integrating inventory management with the Closed-loop Supply Network signifies the multi-optimization framework of supply chain management by incorporating contemporary practices to create value in the competitive global market. However, planning for manufacturing or logistics can easily become difficult for a firm to handle because there are so many aspects to take into account. Apart from that, the Inventory Reorder Point (ROP) calculates the lead time needed to refill while determining the reorder level of the inventory for various SKUs so that you don’t order products at the last minute. Opined by Son & Kim, (2022), the company is effectively focusing on cloud computing services to create an effective and efficient global logistics system that can influence the value chain of the company positively. For example, the company has created a leading position through the efficient logistics system to reach the different international markets according to demand. This factor allows Samsung to forecast the market demand in a more effective way to create value in the competitive market. On the other hand, in a fixed reorder quantity system, fresh orders are placed to replace the inventory to the ideal level based on demand after an alarm is instantly triggered when the level falls below a defined number (Lukiman & Richard, 2020). With its diverse range of electronic products, Samsung signifies the effective incorporation of demand forecasting and supply through effective inventory management.

Conclusion

It is to be concluded that the supply chain management of Samsung is incorporating significant strategies in the logistics functioning in the global market. The impact of the COVID-19 pandemic created an enormous adverse effect on the functioning of different aspects of the global supply chain. However, a supply chain management strategy ensures the incorporation of a wide range of factors from service efficiency to customer satisfaction through delivery, cost, technology, or human resources. The contemporary business operation of Samsung is showing effective adoption of these technologies to create value through global supply chain management. On the other hand, the current trends in supply chain management signify the effective incorporation of sustainable principles in the supply network. Apart from that, the warehousing strategies of the business organization refer to the incorporation of digital technologies for cataloging and procuring materials. On the other hand, enormous changes in demand significantly affected the inventory management of the company where the product life cycle plays a vital role for a large number of product lines of the company. However, it is evident that almost everything available in a store is delivered as a result of a supply chain, and maintaining these networks is a difficult and always-changing operation.

References

https://www.mdpi.com/1424-8220/21/19/6528

Note: Do you need any Assignment Help at affordable prices? Contact us!